Sustainability in Control

The Control division’s companies consist of niche businesses operating primarily in measurement and control technology. Several of the businesses contribute to a more sustainable society by improving the efficiency of resource utilisation through remote measurement, checking and control of equipment.

Sustainability issues in focus

Smart solutions for efficiency, health and climate

Control offers solutions such as environmental measurement technologies for hydrology and meteorology, air quality control systems for indoor environments, and energy-saving control systems for lighting and vehicles. The division’s other offerings include advanced sensor technologies, network solutions and components for control, signal transmission and secure communication – key elements in the development of smarter and more sustainable societies.

Reduced climate impact

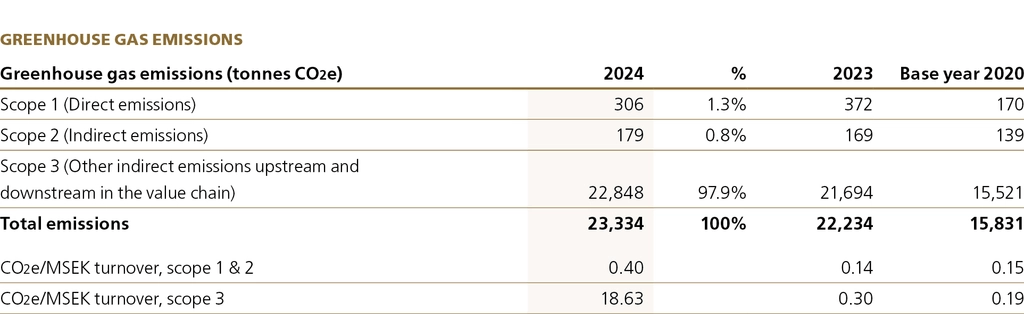

The largest part of the division’s carbon footprint is linked to the purchase of materials, where steel and aluminium constitute the main part. Inbound and outbound transports is another area that accounts for a significant share. The climate impact from energy consumption comes from American and European companies, where natural gas is used in production. Otherwise, green electricity and district heating are used almost exclusively. To reduce climate impact, the companies are working to increase the proportion of recycled content in purchased materials, to streamline transports through co-loading and the choice of less carbon-intensive alternatives, and to make combustion systems more efficient.

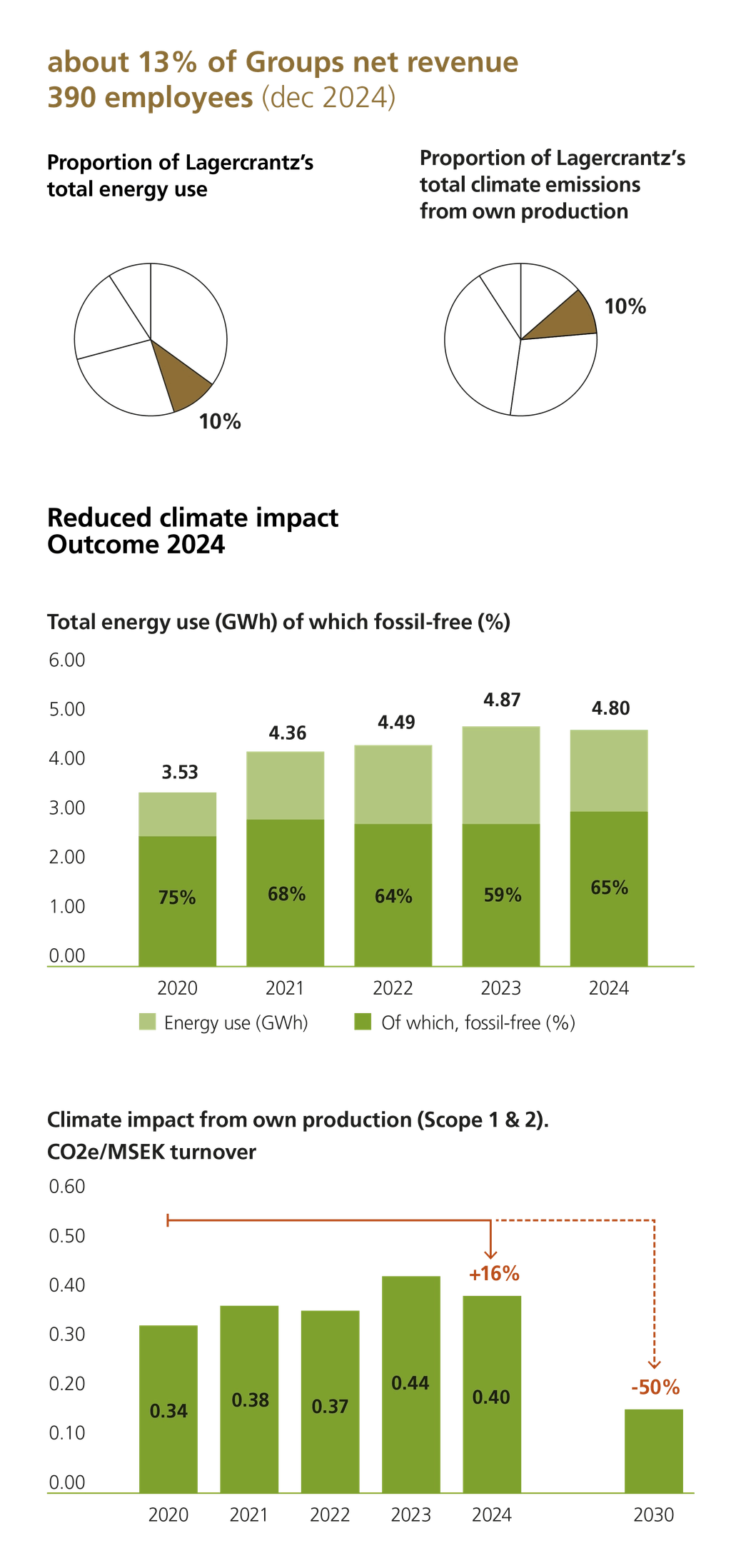

Outcome 2024

- 16% increased climate impact from own production relative to base year 2020. Explained by increased natural gas use in one of the acquired companies.

- 65% (59%) fossil-free energy. Increase driven by a larger share of own production of solar energy and purchased green electricity. The decline compared to the base year is explained by natural gas, as mentioned above.

- Scope 3 has increased by 9% relative to base year 2020, which was explained by a couple of production- and purchasing-heavy units.

Responsible employer and business partner

Control has a significant proportion of its employees in manufacturing. The companies develop a good safety culture by identifying and minimising risks for preventive purposes. All employees are trained in Lagercrantz’s Code of Conduct. In the supply chain, the companies’ suppliers are required to comply with the Code of Conduct.

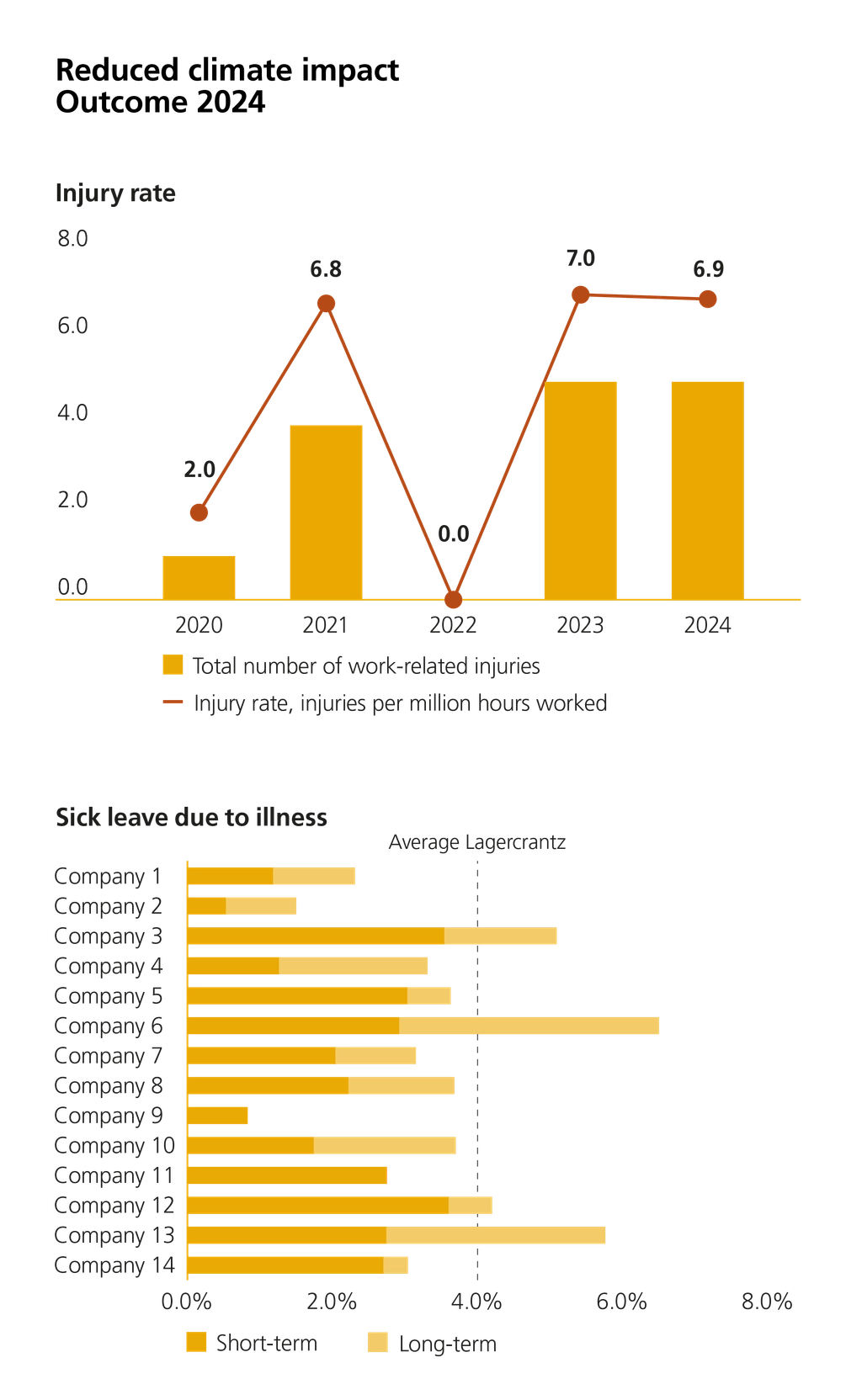

Outcome 2024

- In 2024, the injury rate amounted to 6.9 (7). The accidents during the year can primarily be attributed to one of the production companies. Root cause analysis and corrective actions have been carried out to prevent similar incidents.

- Sick leave due to sickness- and injury rate amounted to 3.9% (4.3). Certain companies in the division have long-term sick leave levels that are stress-related, where targeted work environment efforts are planned.

- The proportion of women in management teams amounted to 17% (17%).