Sustainability in Electrify

The Electrify division has businesses that contribute to the green transition of society, with an emphasis on electrification and development of infrastructure. The division’s companies are largely Nordic manufacturing companies with extensive purchasing of raw materials and input goods for their own production.

Sustainability issues in focus

Products for electrification and infrastructure

The businesses in the Electrify division provide critical products and solutions for electrification and for the development of critical infrastructure. Examples of products for electrification are electrical connectors, road barrier ropes, enclosures, technical buildings, electrical components and cabling. Within infrastructure, complete safety barrier systems, signage for road safety and fibre splicing technology for sea and land are supplied. The division’s companies develop and manufacture products that are crucial for a future, sustainable and safe society.

Reduced climate impact

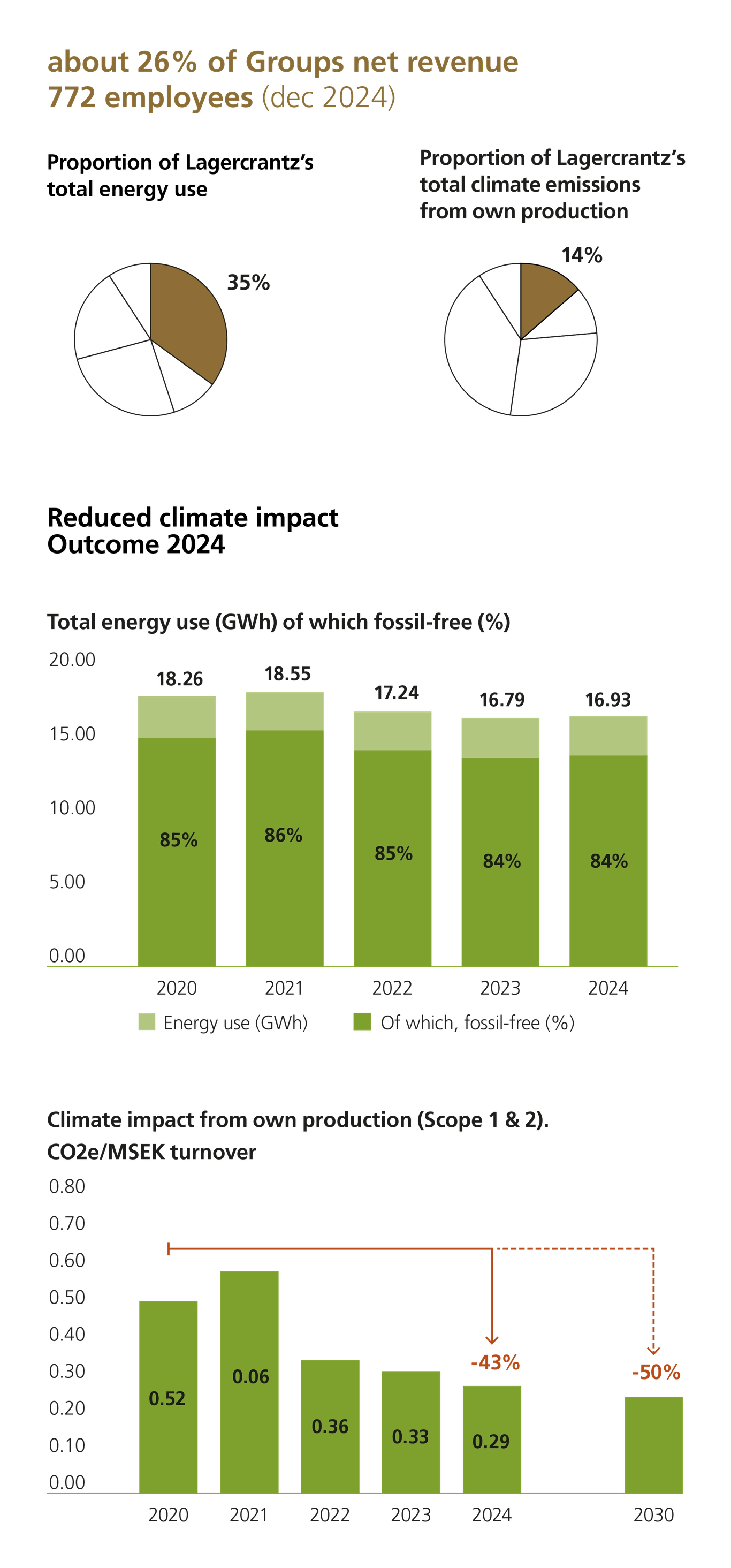

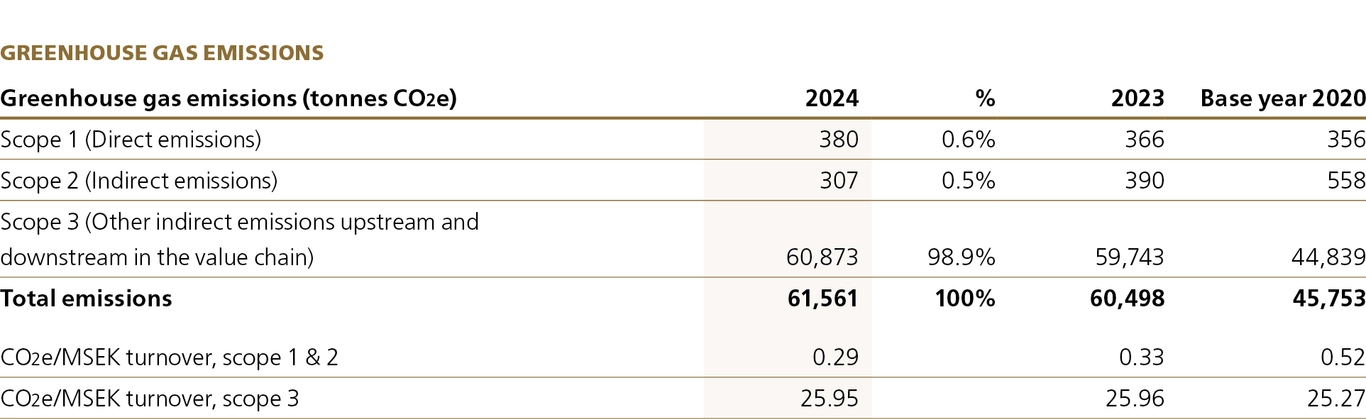

Electrify’s largest climate impact comes from purchasing of materials and transport flows. A significant share of total emissions comes from the purchase of metals in the form of sheet metal, wire, pipes and galvanised steel profiles. For these goods, the origin and production method have a significant impact on the carbon footprint. To reduce this impact, the division is working to increase the use of recycled materials and is choosing efficient production methods in countries with a high share of green energy. Transport choices are optimised by reducing transport distances and gradually phasing out air transport in favour of sea and sustainable land transport. Electrify accounts for 35% of the Group’s total energy use, driven by energy intensive processes such as machining, galvanising, painting and surface treatment. Energy efficiency and the transition to fossil-free energy are important factors in reducing the impact of the division’s own production.

Outcome 2024

- 43% (36%) reduced climate impact from own production relative to base year 2020, explained by energy efficiency improvements and an increased proportion of green electricity.

- 84% (84%) fossil-free energy.

- Scope 3 is relatively unchanged compared to the base year 2020, which can be attributed to several production- and purchasing-heavy companies during the period that have not yet benefited from environmental measures.

Responsible employer and business partner

With a large proportion of employees in production and manufacturing, there is a strong focus on workplace safety and on the work environment. Through systematic work environment efforts and improved working conditions, Electrify is striving to reduce work-related injuries and absence. The companies set high standards for suppliers and apply international labour- and human rights standards.

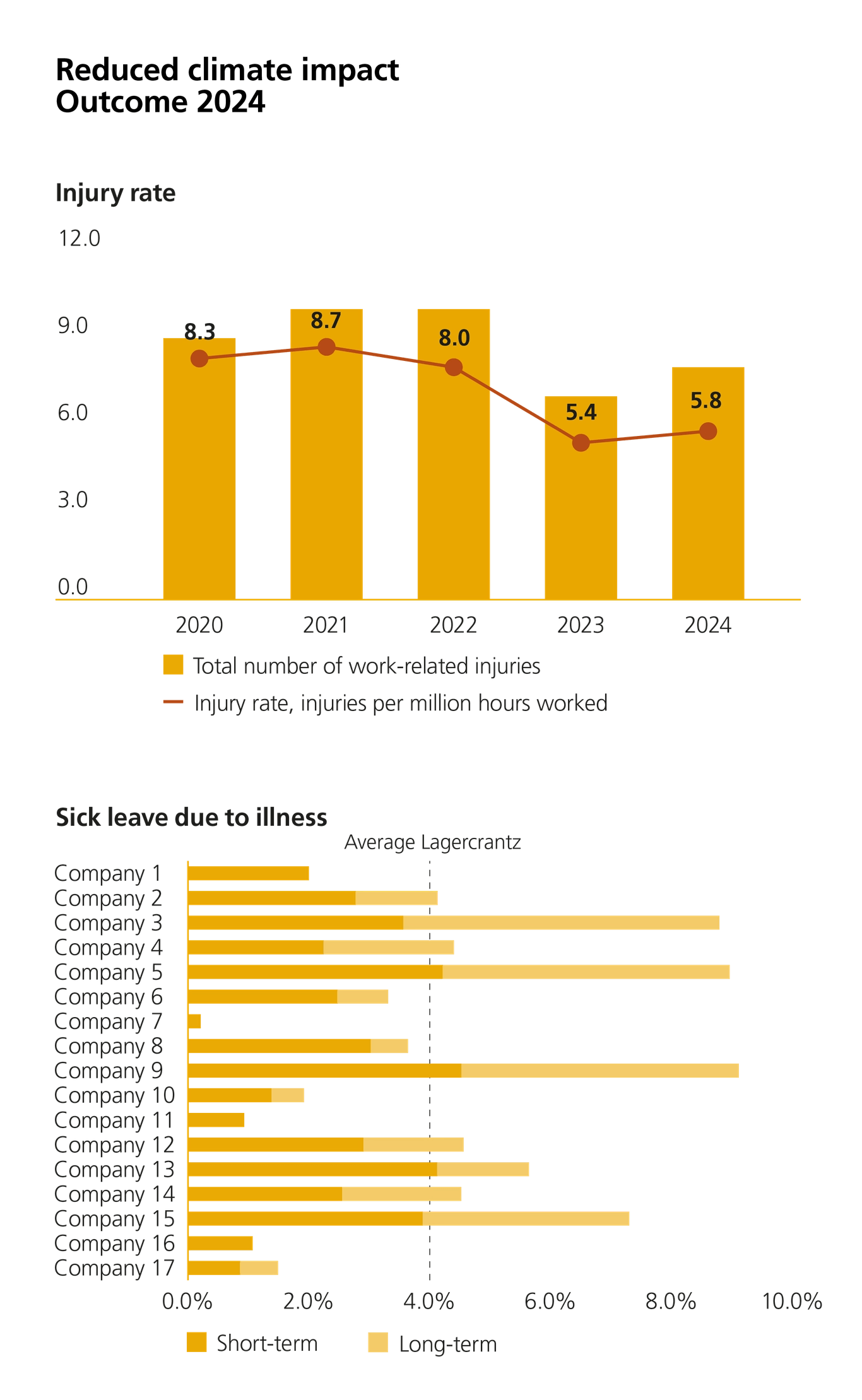

Outcome 2024

- In 2024, the accident rate amounted to 5.8 (5.4). Accidents mainly arise as a result of manual labour in connection with material handling, manufacturing and installation of road barriers.

- Sick leave due to illness in the division totalled 5.1% (5.1%), which is just over the average figure for sick leave due to illness within Lagercrantz. Most of the companies are below the average, but a few have higher absences that affected the overall outcome. Measures for these companies are taken on an ongoing basis during the financial year.

- The proportion of women in management teams amounted to 21% (21%). To increase this level, recruitment to management roles will ensure at least one female applicant with the relevant qualifications. Selection will then be completely gender-neutral.